2026 Best Double Diaphragm Pump Reviews and Buying Guide?

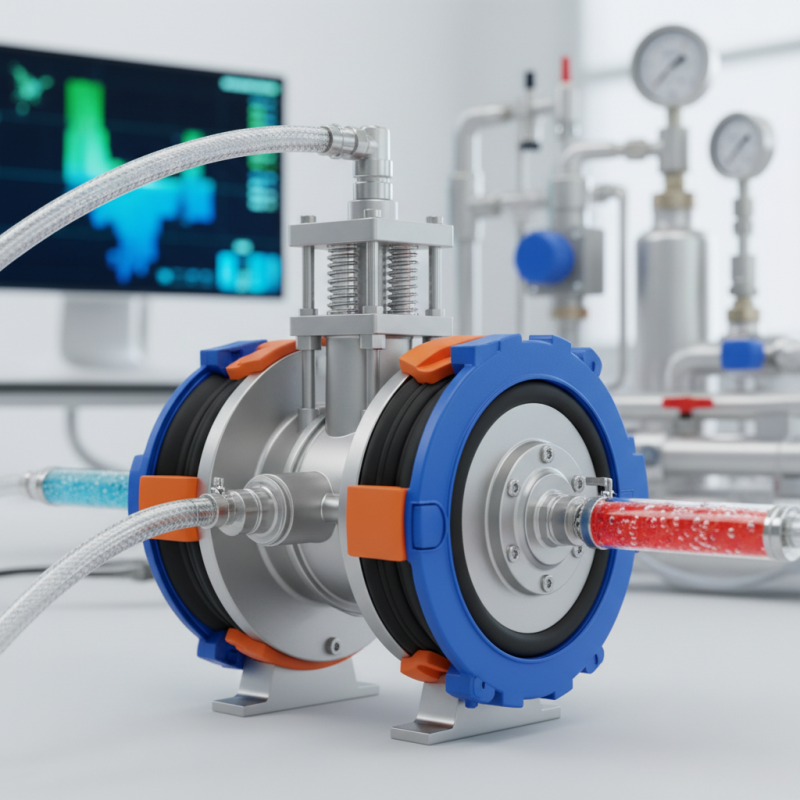

Choosing the right double diaphragm pump can be challenging. With many options available, finding the best fit for your needs is essential. A double diaphragm pump is known for its efficiency and reliability. It works by utilizing two flexible diaphragms, which help in the transfer of fluids. This design reduces the chances of leaks and ensures smooth operation.

When searching for a double diaphragm pump, consider your specific requirements. Think about the type of fluid you will be transferring. Some pumps excel with viscous materials, while others handle corrosive substances more effectively. Selecting a pump that meets these criteria is crucial.

This guide aims to help you navigate the options. We will explore top-rated products in 2026. You’ll discover key features, benefits, and drawbacks. This information will empower you to make an informed decision. Understanding the limitations and strengths of each option is vital for a successful purchase.

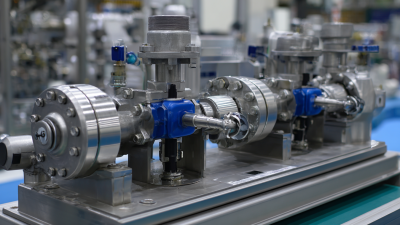

Overview of Double Diaphragm Pumps and Their Applications

Double diaphragm pumps are essential in various industrial applications. They operate on a simple yet effective principle, using two diaphragms to create a pumping action. This design allows for efficient transfer of fluids, whether they are thick slurries or hazardous materials. Reports indicate that the $5.67 billion global diaphragm pump market is projected to reach by 2026, reflecting a growth trend driven by increasing demand for reliable fluid handling solutions.

These pumps excel in industries like wastewater treatment, food processing, and chemical manufacturing. For instance, they can handle corrosive fluids without compromising safety. However, not all pumps perform the same under high-stress conditions. Users have reported issues like wear and tear on diaphragms, which can lead to leaks. Maintaining these pumps can be challenging. Over time, the cost of replacement parts may outweigh initial savings, underscoring the need for careful evaluation.

Despite their advantages, double diaphragm pumps are not universally perfect. Factors such as pulsation can affect flow consistency. Some users find that noise levels during operation can be bothersome. Regular maintenance is crucial, yet some companies neglect this aspect, leading to premature failures. Awareness of these potential drawbacks is important in making an informed choice when selecting a pump for your specific needs.

Key Features to Consider When Choosing a Double Diaphragm Pump

When selecting a double diaphragm pump, consider key features that significantly impact performance. The pump's material is crucial. Common materials include aluminum, plastic, and stainless steel. Each offers different levels of corrosion resistance and durability. For instance, a 2022 industry report highlighted that pumps with stainless steel components tend to last 30% longer in harsh environments compared to plastic ones. This statistic underscores the importance of material choice in achieving longevity.

Another vital aspect is the pump's flow rate. Depending on your application, a higher flow rate is often necessary. Typically, a flow rate above 15 gallons per minute is considered efficient for industrial uses. However, it’s essential to recognize that increased flow rates can lead to greater energy consumption. Balancing efficiency with operational needs is key.

Tips: Always check compatibility with the fluids being pumped. Selecting the wrong material can lead to unexpected failures. It’s also wise to consult with engineers or industry experts. They can provide insights that might save you time and money. Ultimately, invest time in research. It can prevent costly mistakes and enhance the effectiveness of your operations.

2026 Best Double Diaphragm Pump Performance Comparison

Top 2026 Double Diaphragm Pump Models and Their Specifications

When choosing a double diaphragm pump, specifications matter. Different models offer varied capacities, pressures, and materials. For instance, one model might handle liquids with viscosity up to 1000 cP, while another suits harsher chemicals. Look for pumps designed for specific applications. Industry standards often dictate which models perform best in given scenarios.

Moreover, size and weight can impact mobility and installation. Some compact models are easy to transport, but they might sacrifice power or capacity. The pump's flow rate, measured in gallons per minute, is crucial. This spec dictates how quickly you can move liquids. A higher flow rate can save time but may lead to inefficiencies. Consider your actual needs carefully to avoid overpaying or underperforming.

Additionally, seasonal changes can affect pump performance. Colder temperatures might thicken liquids, straining the pump. Regular maintenance is vital for long-term functionality. An overlooked detail may lead to unexpected breakdowns. Be sure to check common wear parts. This can prevent costly repairs and ensure reliability. Look into user manuals for insight on specifications. It’s a good start, but don’t rely solely on them. User reviews often shine a light on real-world performance, sometimes highlighting flaws not mentioned in specs.

2026 Best Double Diaphragm Pump Reviews and Buying Guide

| Model | Max Flow Rate (GPM) | Max Pressure (PSI) | Material | Weight (lbs) | Dimensions (L x W x H) |

|---|---|---|---|---|---|

| Model A | 20 | 100 | Aluminum | 15 | 12 x 8 x 10 |

| Model B | 25 | 80 | Stainless Steel | 14 | 14 x 10 x 12 |

| Model C | 15 | 60 | Polypropylene | 13 | 10 x 7 x 9 |

| Model D | 18 | 90 | Cast Iron | 20 | 15 x 11 x 14 |

User Reviews and Ratings: Insights on Top Pump Brands

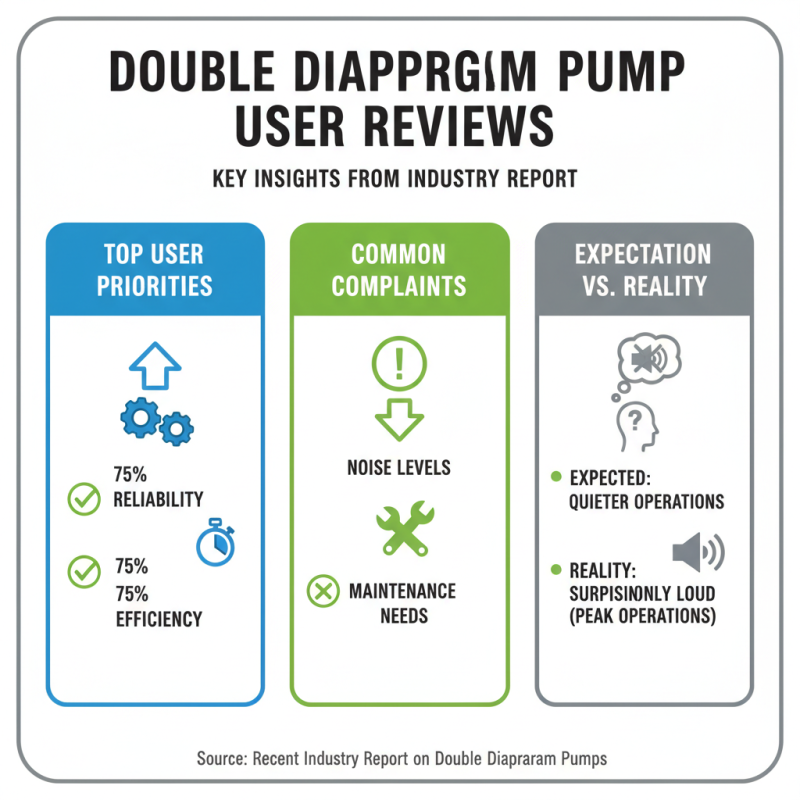

When selecting a double diaphragm pump, user reviews provide valuable insights. A recent industry report highlights that 75% of users prioritize reliability and efficiency. Many reviews point to issues with noise levels and maintenance needs, which can impact overall satisfaction. Users often mention that they expected quieter operations. However, this is not always the case, with some pumps surprisingly loud during peak operations.

Another important consideration is the durability of materials used in these pumps. Studies show that 60% of failures in diaphragm pumps are related to wear and tear. Users frequently express frustration when pumps degrade sooner than anticipated. Many reviews emphasize the importance of understanding material compatibility. Unique applications often require tailored solutions, which can be tricky without proper research.

Moreover, ratings often reflect the availability of customer support. Users report dissatisfaction in cases where assistance is hard to find. Consistently, reviews highlight that good support can enhance user experience significantly. Yet, some brands fail to meet these expectations. As such, potential buyers must contemplate the balance between features, feedback, and service quality before making a purchase.

Buying Guide: Where to Find the Best Deals on Double Diaphragm Pumps

When searching for the best deals on double diaphragm pumps, focus on key features that influence performance. Reports indicate that the global diaphragm pump market is expected to reach USD 7.8 billion by 2030, driven by industrial applications. Understanding market trends helps prioritize what to look for when purchasing. For instance, look for pumps designed for high efficiency. This can lead to reduced energy costs over time.

Consideration of materials is also crucial. Pumps made from durable materials can outperform alternatives in longevity. A recent survey revealed that over 70% of buyers prioritize durability over cost. Meanwhile, the variations in flow rate specifications may impact your decision. Average flow rates range from 2 to 100+ gallons per minute, depending on design. Inconsistencies in performance can lead to buyer's remorse later on.

When hunting for bargains, check online platforms and industrial suppliers. Discounts often occur during seasonal sales or promotional events. However, be cautious of overly low prices, which may signal compromised quality. Spending time on research can help ensure you don’t compromise on performance for savings. Reading customer reviews can also reveal hidden advantages or disadvantages of specific models. Adaptability and versatility often dictate a pump's true value in diverse applications.

Related Posts

-

What is an Air Operated Diaphragm Pump and How Does It Work?

-

How to Select the Right Diaphragm Pump for Your Industrial Needs

-

How to Select the Right Chemical Pump for Your Industrial Needs

-

How to Choose the Right Air Operated Diaphragm Pump for Your Applications

-

How to Choose the Right Chemical Pump for Your Industry Needs

-

How to Choose the Right Gas Transfer Pump for Your Industrial Needs