2026 Best Metering Pumps for Precision Fluid Transfer?

In the world of fluid transfer, precision is key. Metering pumps are essential for achieving accurate flow control in various applications. These devices offer consistent and reliable performance across numerous industries. In 2026, several metering pumps stand out in terms of innovation and efficiency.

Choosing the right metering pump requires careful consideration. Factors like flow rate, fluid properties, and budget play a crucial role. Different metering pumps excel in different environments. Some may struggle with viscous fluids or abrasive chemicals. It’s important to reflect on these limitations.

The landscape of metering pumps continues to evolve. New technologies improve their accuracy and durability. However, not all pumps are created equal. Users often face challenges in selecting the best fit for their specific needs. A tailored approach will lead to better outcomes and enhanced operational efficiency.

Overview of Metering Pumps and Their Applications

Metering pumps play a crucial role in diverse industries. Their primary function is to transfer fluids with precision. This capability is vital in sectors such as pharmaceuticals, water treatment, and chemical processing. According to a recent market study by Grand View Research, the global metering pump market is expected to reach $5.1 billion by 2025. This growth reflects the increasing need for automation in fluid handling.

Applications of metering pumps vary widely. In food and beverage processing, they help maintain product consistency. The pharmaceutical industry relies on them for accurate dosing of active ingredients. In water treatment, they regulate chemicals used for purification. Each application demands a specific type of pump for optimal performance. This underscores the importance of selecting the right metering pump.

**Tip:** Regular maintenance of metering pumps can prevent unexpected downtime. Check seals and calibrations regularly. Understand your unique requirements before investing in any system.

However, not all metering pumps are created equal. Some may over- or under-deliver fluids. This inconsistency can lead to production inefficiencies. It is essential to evaluate pump specifications carefully. Therefore, understanding the specific application and environmental factors is critical. Despite advancements, user errors in setup and operation still occur. Continuous training is necessary to ensure optimal use.

2026 Best Metering Pumps for Precision Fluid Transfer

| Pump Type | Max Flow Rate (L/h) | Fluid Viscosity (cP) | Pressure Range (bar) | Control Type |

|---|---|---|---|---|

| Diaphragm Pump | 100 | 200 | 15 | Manual & Automatic |

| Gear Pump | 80 | 100 | 20 | Automatic |

| Peristaltic Pump | 50 | 300 | 5 | Manual |

| Rotary Lobe Pump | 120 | 250 | 25 | Automatic & Manual |

| Screw Pump | 30 | 500 | 30 | Automatic |

Key Features to Consider in Metering Pumps for Fluid Transfer

When selecting metering pumps for fluid transfer, precision is key. The right pump can dramatically impact efficiency and accuracy. It's crucial to focus on several features. Flow rate consistency is vital. According to industry reports, a variance in flow rates can lead to significant processing errors. A metering pump should ideally provide a flow rate with a maximum deviation of just 2%. This ensures materials are transferred accurately.

Another important aspect is the pump's materials. Compatibility with various fluids is essential. Many manufacturers overlook this when making their choices. Materials such as PVC, stainless steel, or PTFE can affect pump longevity and performance. A recent study highlighted that improper material selection can lead to a 30% increase in maintenance costs. This adds unnecessary expenses to the operation budget.

Lastly, consider the control mechanisms. Automation integration is becoming standard in many operations. It adjusts flow in real-time, leading to better precision. Yet, not all pumps offer advanced control systems. Many users have reported frustrations with manual systems. They often wish for more user-friendly interfaces. A lack of easy-to-use controls can hinder operational efficiency. Continuous evaluation of these features is necessary to ensure optimal performance in fluid transfer processes.

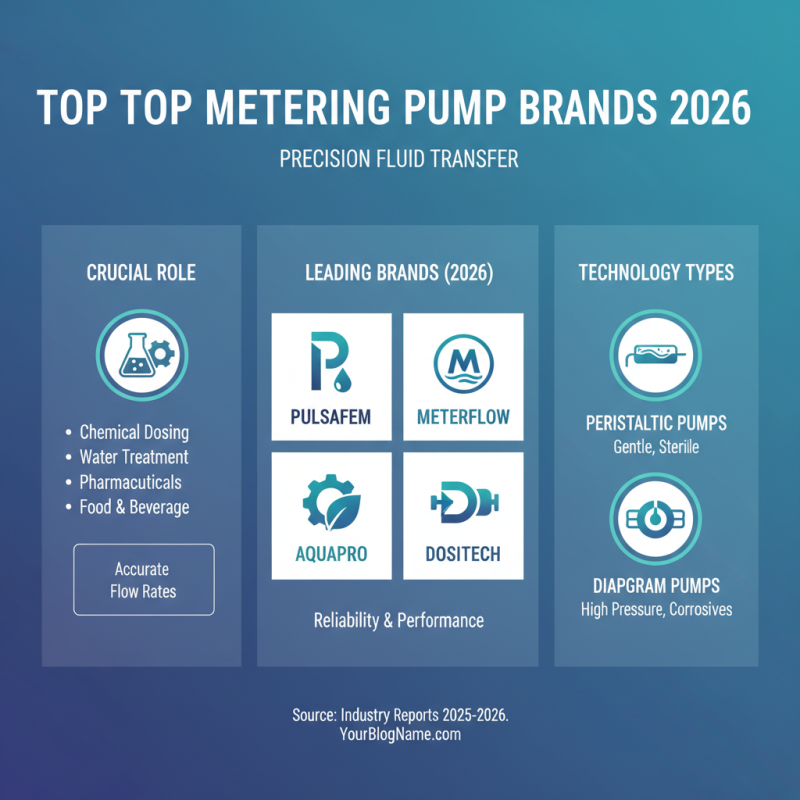

Top Brands and Models of Metering Pumps in 2026

When it comes to precise fluid transfer, metering pumps play a crucial role in various industries. In 2026, several brands stand out for their reliability and performance. These pumps are designed to provide accurate flow rates, which is essential for applications such as chemical dosing and water treatment. Different models feature various technologies, from diaphragm to peristaltic mechanisms.

One notable aspect of these pumps is their user-friendly design. Many meters come equipped with digital controls, allowing for easy adjustments. This functionality appeals to operators. However, some models may have complex calibration procedures, which could be frustrating for new users. It's essential to weigh these factors before making a choice.

Users often appreciate enhanced durability in metering pumps. Models made with high-quality materials can withstand harsh environments. Yet, some may face maintenance issues that require regular attention. This aspect can result in unexpected downtime and additional costs. Therefore, being informed about the strengths and weaknesses of these models is vital for optimal performance.

Comparative Analysis of Metering Pumps Performance and Efficiency

When evaluating metering pumps, performance and efficiency are critical. Different types of pumps can significantly vary in how they handle fluid transfer. Understanding these variations helps in selecting the right equipment for specific applications. For instance, diaphragm pumps are praised for their accuracy, while gear pumps excel in high-viscosity fluids. Each design has strengths and weaknesses, influencing operational outcomes.

In addition to the type, factors like pressure and flow rate play vital roles in pump efficiency. Studies indicate pulsation can affect performance. Many users might overlook this detail. A pump that works well in theory may underperform in practice if not properly calibrated. Monitoring the operating conditions regularly is essential. Users often realize the need for adjustments only after encountering issues.

Moreover, maintenance practices directly impact the longevity and reliability of metering pumps. Neglecting regular checks can lead to inconsistent fluid transfer. Such lapses often cost more time and resources ultimately. A balance between efficiency and thorough upkeep is necessary for optimal function. Reflecting on these factors can lead to better, more informed choices.

2026 Best Metering Pumps for Precision Fluid Transfer

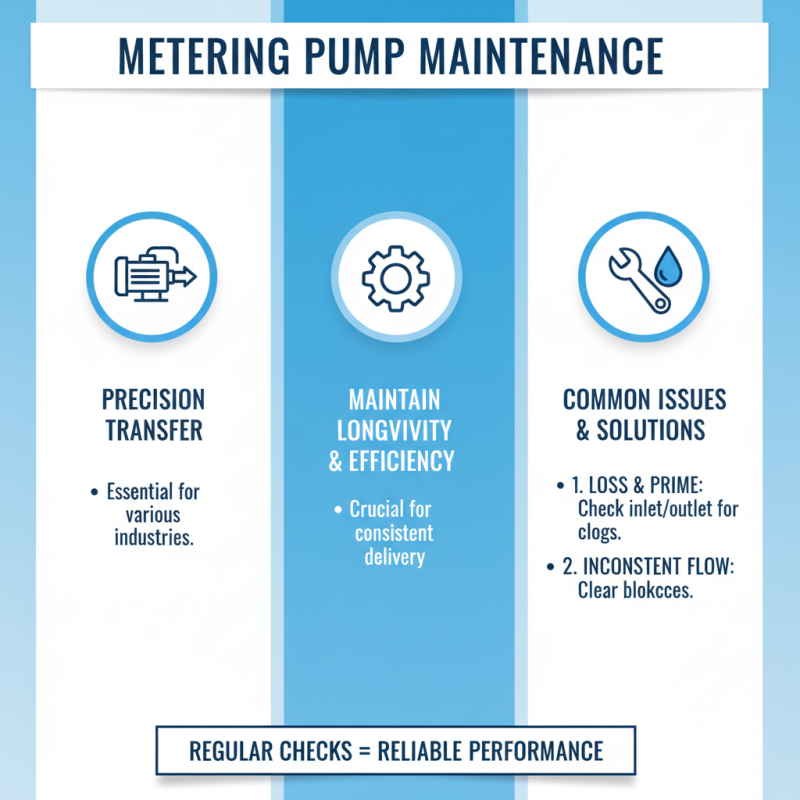

Maintenance and Troubleshooting Tips for Metering Pumps

Metering pumps are essential for precise fluid transfer in various industries. Proper maintenance is crucial to ensure their longevity and efficiency. A common issue is the loss of prime, which can lead to inconsistent fluid delivery. Regularly check the inlet and outlet connections for any blockages. A small clog can cause significant disruptions.

Another vital maintenance tip is to inspect the pump’s seals and gaskets for wear and tear. Look for any signs of leakage around these areas. Replacing worn components may seem minor but can prevent more extensive damage. Additionally, ensure that the pump is correctly calibrated to match the desired flow rate. Incorrect settings can lead to over or under-dosing, affecting overall processes.

Troubleshooting metering pumps often involves listening for unusual noises. Odd sounds may indicate a mechanical issue that requires immediate attention. Vibration or erratic flow can also signal underlying problems. Addressing these issues promptly helps maintain operational standards. Regular training on these maintenance tips can empower staff. Routine checks can prevent unexpected downtime and costly repairs.

Related Posts

-

Top 10 Tips for Choosing the Right Metering Pump for Your Needs

-

Top Strategies for Enhancing Efficiency with Metering Pumps

-

How to Choose the Right Chemical Pump for Your Industry Needs

-

How to Choose the Right Vacuum Pump for Your Needs: A Complete Guide

-

How to Choose the Right Air Operated Diaphragm Pump for Your Applications

-

How to Choose the Right Gas Pump for Your Business Needs