2026 Best Progressive Cavity Pump Options for Your Needs?

In the evolving landscape of industrial pumping solutions, the progressive cavity pump stands out for its versatility and efficiency. According to industry expert Dr. Michael H. Roberts, “Selecting the right progressive cavity pump can greatly enhance operational productivity.” His insights remind us that understanding pump specifications is key to achieving optimal performance.

In 2026, the market offers numerous progressive cavity pump options. Industries ranging from wastewater treatment to food processing heavily rely on these pumps for their unique capabilities. Each application demands specific characteristics, making it essential to evaluate your unique needs.

However, the selection process can be daunting. Not all pumps are created equal, and the variety can lead to regrettable choices. Reflection on past experiences may be necessary. The optimal pump should not only fit the technical requirements but also align with your operational goals.

2026 Best Progressive Cavity Pump Options: Market Overview and Trends

As industries evolve, so do the needs for effective pumping solutions. Progressive cavity pumps are increasingly popular due to their efficiency and versatility. In 2026, various sectors are embracing these pumps for transferring complex fluids. The ability to handle both high-viscosity materials and solids is a significant advantage in many applications. From wastewater management to food processing, their adaptability makes them a necessity.

Current market trends indicate a rising demand for pumps that combine durability with energy efficiency. Many users find themselves overwhelmed by choices. Some pumps claim to optimize performance, yet real-world results may vary. It's essential to evaluate operational costs versus initial investment. A pump that saves money upfront may lead to higher long-term expenses.

Additionally, the integration of smart technology is transforming pump operations. Remote monitoring systems are becoming standard, ensuring better maintenance and responsiveness. However, not all users are ready for such advancements. It requires training and change in established routines. As we explore options in progressive cavity pumps, a thoughtful assessment of both current and future needs is crucial.

Key Features for Selecting Progressive Cavity Pumps in 2026

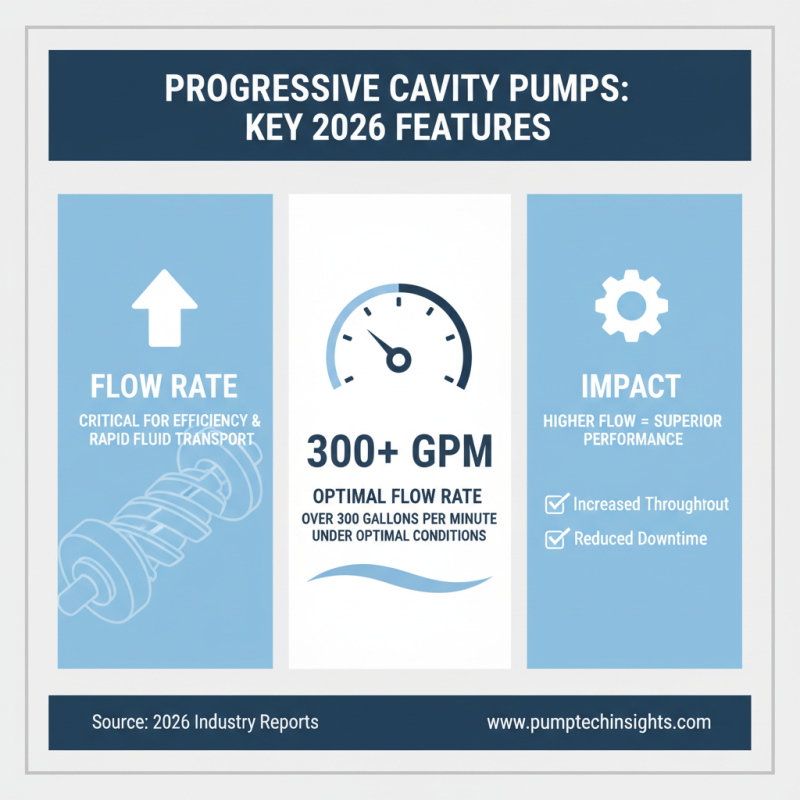

When selecting progressive cavity pumps in 2026, key features can significantly impact performance. One critical aspect is the pump's flow rate, which determines efficiency. According to industry reports, pumps with higher flow rates can handle over 300 gallons per minute in optimal conditions. This statistic is essential for operations that require rapid fluid transport.

Another vital factor is the pump's tolerance to varying viscosities. Many operations deal with fluids that change in thickness. Reports suggest that pumps with a viscosity range of up to 1,000 centipoise can perform better in industries such as food processing or wastewater management. This flexibility not only enhances functionality but also reduces maintenance frequency.

Durability is another critical feature. Progressive cavity pumps operate in harsh environments, so materials need to be resilient. Steel and specialized polymers are popular choices, yet they may wear out faster than expected. Some users have reported issues with corrosion and abrasion that compromise performance. Continuous monitoring and regular maintenance are necessary to address these shortcomings. Understanding these key features will help you make more informed choices.

Top Applications Driving Demand for Progressive Cavity Pumps

Progressive cavity pumps are essential in many industries. They excel in handling viscous fluids. The food and beverage sector frequently utilizes these pumps for their reliable flow. According to a recent industry report, the demand for progressive cavity pumps is projected to grow by 5.4% annually through 2026. This growth is driven by their efficiency in various applications.

Another key area is the wastewater treatment industry. Progressive cavity pumps are effective in moving slurries and solids. They ensure steady flow and can manage varying pressure levels. This adaptability makes them invaluable in environmental applications. Experts note that over 30% of all pumps used in this sector are progressive cavity types.

**Tip:** When selecting a progressive cavity pump, consider the fluid's viscosity and temperature. These factors greatly influence pump performance. Understanding your application can prevent costly mistakes and lead to better efficiency.

Industries must also reflect on maintenance practices. Despite their reliability, progressive cavity pumps can face wear. Regular inspections are crucial. They help identify issues before they become serious. Not all users prioritize maintenance, leading to unexpected downtimes.

Comparative Analysis of Leading Brands in Progressive Cavity Pump Market

When considering progressive cavity pumps, evaluating leading options is crucial. Efficiency varies significantly among brands. Some pumps excel in specific applications, while others may struggle. Understanding these differences aids informed choices.

Many factors influence performance. Flow rates, viscosity handling, and maintenance needs are key considerations. Some pumps are designed for delicate liquids, while others tackle more robust substances. Brands often market their strengths well, but deeper research reveals nuances. Users sometimes find unexpected challenges with certain models.

Customer feedback is invaluable yet mixed. Some users praise reliability, while others cite issues with wear and tear. It’s essential to weigh these opinions against your specific requirements. An ideal pump in one scenario may not be sufficient in another context. It's a reminder to carefully analyze your needs before making a commitment.

2026 Best Progressive Cavity Pump Options for Your Needs

| Pump Type | Max Flow Rate (m³/h) | Pressure Rating (bar) | Viscosity Range (cP) | Material | Applications |

|---|---|---|---|---|---|

| Standard Progressive Cavity Pump | 30 | 10 | 1000 - 50000 | Stainless Steel | Food Processing |

| High-Pressure Progressive Cavity Pump | 25 | 20 | 500 - 100000 | Ductile Iron | Oil and Gas |

| Chemical Progressive Cavity Pump | 20 | 8 | 100 - 30000 | PVC | Chemical Processing |

| Slurry Progressive Cavity Pump | 15 | 12 | 1000 - 2000 | Carbon Steel | Mining |

| Multi-Phase Progressive Cavity Pump | 40 | 15 | 200 - 50000 | Alloy Steel | Wastewater Treatment |

Maintenance Best Practices for Maximizing Efficiency of Cavity Pumps

Maintaining progressive cavity pumps is crucial for their efficiency and longevity. Regular inspections can catch potential issues before they become serious problems. Check for leaks and unusual noises regularly. These signs often indicate wear or misalignment. Ignoring them can lead to downtime and costly repairs.

Lubrication is another critical aspect. Proper lubrication minimizes friction and wear between components. Use the manufacturer’s recommended lubricant. Too little or too much can cause performance issues. Pay attention to the lubrication schedule. It’s easy to overlook, but essential for smooth operation.

Cleanliness is vital as well. Contaminants can damage the pump and affect its performance. Keep the surrounding area clean. Ensure that the inlet is free from debris. Even minor particles can cause significant issues over time. Regularly review maintenance logs. Reflecting on past problems can help identify patterns and prevent future breakdowns.

2026 Best Progressive Cavity Pump Efficiency Metrics

Related Posts

-

How to Choose the Right Chemical Pump for Your Industry Needs

-

Everything You Need to Know About Transfer Tank Pumps: Your Ultimate Guide to Safe Fuel Handling

-

Understanding the Importance of Proper Maintenance for Your Diesel Tank System

-

Why Understanding Diesel Tanks is Essential for Your Business Operations

-

Top 5 Gas Transfer Pumps for Efficient Fuel Transfer and Handling

-

2025 Top Gas Pump Innovations: What You Need to Know for the Future