2026 Top Diesel Transfer Tank with Pump Buying Guide?

In recent years, the demand for a reliable diesel transfer tank with pump has surged in various industries. The global market for fuel transfer systems is expected to grow significantly, reaching approximately $XX billion by 2026. This increase reflects the growing need for effective and safe fuel management solutions. Companies are looking for tanks that not only transport diesel efficiently but also adhere to safety regulations.

Various reports indicate that improper handling of diesel can lead to environmental hazards. Choosing the right diesel transfer tank with pump ensures compliance with industry standards. A well-designed system minimizes the risks associated with spills or leaks. However, many users overlook the importance of this equipment in their operations.

When considering a purchase, potential buyers should reflect on their specific needs. Are they focused on capacity, mobility, or compatibility with existing fuel systems? The wrong choice can lead to significant challenges. As we explore the top options in this buying guide, keep in mind that understanding your requirements is crucial. A thoughtful, informed decision is key to effective fuel management.

Understanding Diesel Transfer Tanks: Key Features and Functions

Diesel transfer tanks play a vital role in the transportation of fuel. Understanding their key features is crucial for users. A well-designed unit includes safety, capacity, and portability as core attributes. According to industry reports, the market for diesel transfer tanks is growing at a rate of 4.6% annually. This rise indicates an increased reliance on these tanks for fueling equipment.

Safety features are paramount. Tanks often come equipped with pumps that include automatic shut-off mechanisms. This prevents overfilling and spills, which can be costly and dangerous. Additionally, using a tank with a built-in filtration system ensures cleaner fuel for your engine. Many users overlook this aspect. Regular maintenance can significantly impact performance.

Capacity is another crucial factor. Common sizes range from 50 to 1,000 gallons. Choosing the right size depends on your needs. However, an oversized tank can become cumbersome. Portability features, like sturdy handles or wheels, can make a difference. In contrast, some models lack these conveniences, making them hard to maneuver. Users should consider how often they need to relocate their tanks. Understanding these elements can enhance your overall experience.

Types of Diesel Transfer Tanks: A Comprehensive Overview

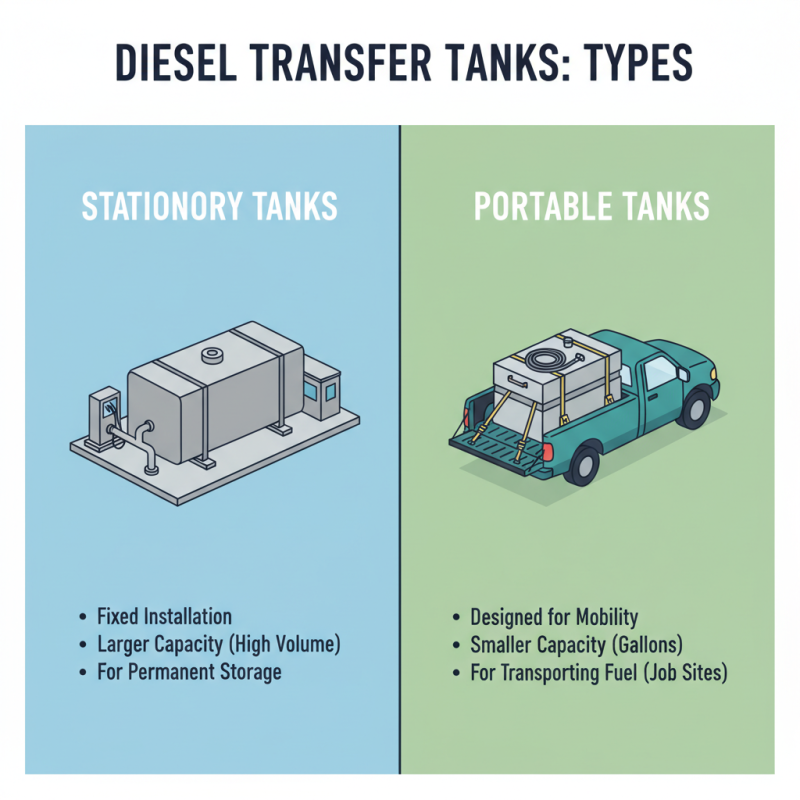

When considering diesel transfer tanks, it's vital to understand the various types available. These tanks typically fall into two main categories: stationary and portable. Stationary tanks are designed for fixed installations. They are often larger and can hold significant volumes of diesel. Portable tanks, on the other hand, are designed for mobility. They usually come with robust mounting options, making them ideal for transporting fuel between job sites.

According to the National Fire Protection Association (NFPA), safety is paramount when handling diesel fuel. Tanks must meet stringent guidelines. Common materials include steel and polyethylene; both offer unique benefits. Steel tanks are durable but may corrode. Polyethylene tanks are lighter and resistant to rust. However, their longevity can be a concern under UV exposure.

**Tip:** Consider the regulations in your area. Compliance affects your purchase. Also, evaluate pump options carefully. A high-quality pump can enhance efficiency and safety. Remember, not every pump fits all tanks. Some have specific flow rates or pressure requirements.

While many tanks boast features, assess whether they suit your needs. A tank that seems perfect might not tackle your usage scenario efficiently. Think about capacity, material type, and your typical environment. A hasty choice could lead to inefficiencies or safety issues later.

Factors to Consider When Buying a Diesel Transfer Tank with Pump

When looking to buy a diesel transfer tank with pump, several factors should be considered. First, size matters. Capacity varies widely. A larger tank can reduce the frequency of refills, but fitting it in your vehicle or space is crucial. Think about your needs. A standard size might suffice for one task, but multipurpose use may require a bigger option.

Next, focus on the pump type. Electric pumps offer convenience, while manual pumps may be simpler. Each has pros and cons. Electric pumps provide quicker transfers but rely on a power source. Manual pumps could require more effort but are often more reliable in remote areas. Assess the locations where you'll use it.

Safety features can't be ignored. Look for tanks with built-in measures to prevent spills and leaks. These features could save you from accidents and costly cleanup. Additionally, consider the durability of materials. Stainless steel tanks tend to last longer but come at a higher cost. Give thought to your budget and the return on investment. Choosing wisely now can prevent future regret.

2026 Diesel Transfer Tanks with Pump Comparison

Top Brands and Models of Diesel Transfer Tanks for 2026

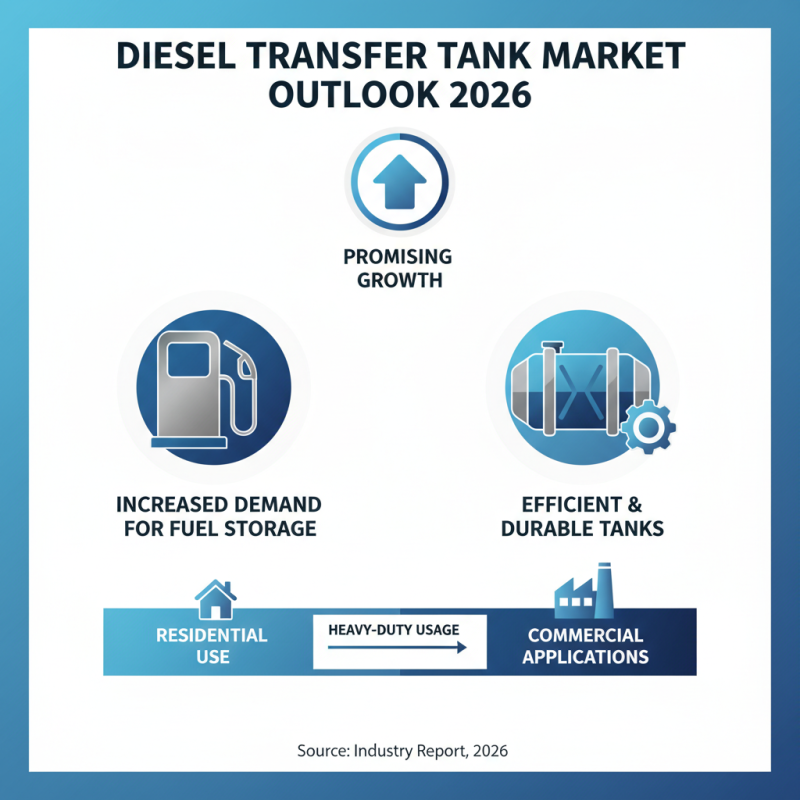

The market for diesel transfer tanks in 2026 shows promising growth. A recent industry report highlights an expected increase in demand for fuel storage solutions. User preferences are shifting towards tanks that are more efficient and durable. Many models are designed for heavy-duty usage. This trend indicates a focus on both residential and commercial applications.

Safety and convenience remain key factors when choosing a diesel transfer tank. Many consumers are prioritizing features like spill containment and secure installation. According to latest statistics, tanks with advanced pumping systems can reduce transfer times by 25%. This efficiency is crucial for users with high-volume needs.

Tips: Always check for certifications on any tank you consider. Quality assurance matters greatly. Also, evaluate your space before purchase. A tank that fits poorly creates various problems. Remember to consider future fuel needs too. Planning ahead can save you money and hassle.

Maintenance Tips for Diesel Transfer Tanks to Ensure Longevity

Maintaining your diesel transfer tank is crucial to its longevity. Regular inspections should be a part of your routine.

Check for leaks, rust, or cracks. Small issues can turn into costly repairs over time.

Keeping the tank clean is equally important. Residue buildup can affect pump performance and fuel quality.

Use a quality filter to prevent contaminants from entering the tank.

Filters should be changed regularly to ensure optimal function. Monitor the fuel level frequently.

Empty tanks can accumulate moisture, leading to serious damage. Consider using a tank cover to protect against elements that may cause premature wear.

Storage conditions matter. Place the tank in a dry, shaded area to avoid UV damage and corrosion.

Avoid overfilling; this creates pressure that can lead to leaks. Be aware of local regulations regarding fuel storage.

Failure to comply can cost you significantly.

Regular maintenance helps ensure safe and efficient use of your diesel transfer tank, ultimately saving you from frustrations down the line.

Related Posts

-

Top 10 Diesel Transfer Tanks with Pumps for Efficient Fuel Management

-

Ultimate Diesel Transfer Pump Tips for Efficient Fuel Handling?

-

Essential Tips for Choosing a Diesel Transfer Pump?

-

Exploring the Impact of Diesel Tank Innovations at the 138th Canton Fair 2025 in China

-

Top Gear Pump Types Explained for Efficient Fluid Transfer?

-

Innovations in Fuel Storage Tanks Showcased at the 138th Canton Fair in 2025