Best Centrifugal Pumps in 2026 What You Need to Know?

In the evolving landscape of industrial equipment, understanding centrifugal pumps is crucial. As we approach 2026, the demand for efficient pumping solutions is increasing. Centrifugal pumps play a significant role in various applications, from water treatment to chemical processing.

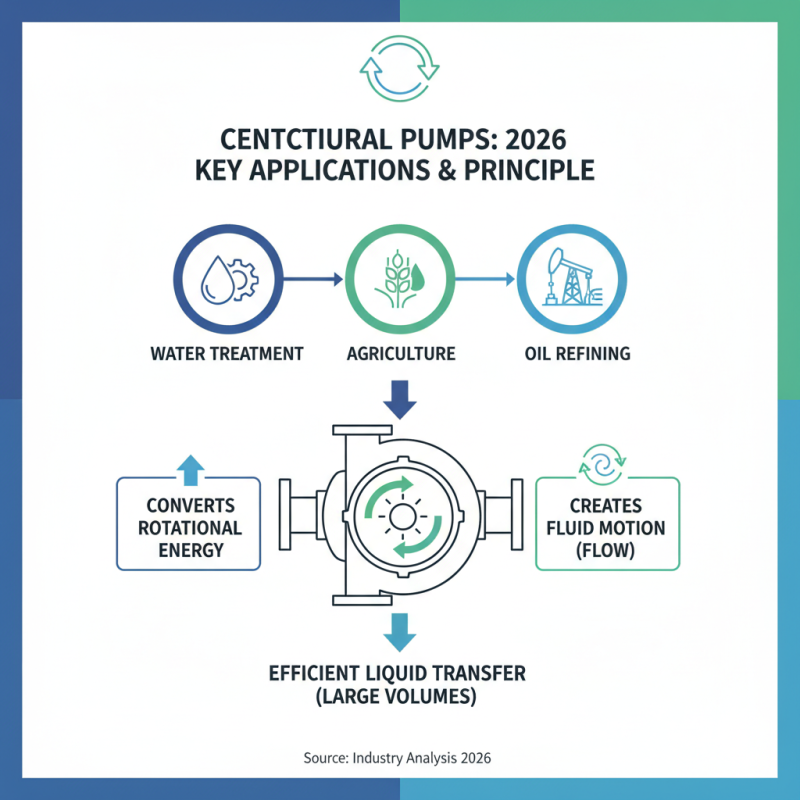

These pumps operate on simple principles, converting rotational energy into fluid motion. This process makes them popular for their reliability and efficiency. However, selecting the right model can be challenging. Factors like material compatibility and flow rate must be considered.

Enhancements in technology are reshaping the pump industry. Reviews and comparisons of current models are essential to make informed decisions. Potential buyers should be aware of common pitfalls. Poor choices can lead to increased maintenance costs and operational downtime. Understanding these aspects is vital for anyone navigating the centrifugal pump market.

Best Centrifugal Pumps in 2026: Market Overview and Trends

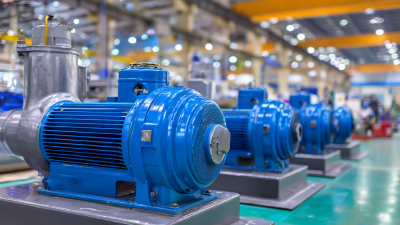

The centrifugal pump market in 2026 is rapidly evolving. Manufacturers are focusing on energy efficiency. This aligns with global sustainability goals. More facilities are adopting these pumps for varied applications. Water treatment and food processing are leading sectors.

Advancements in technology drive innovation in pump design. Smart pumps are emerging, featuring IoT capabilities. These pumps offer real-time monitoring and performance data. Users can analyze efficiency and make informed decisions. However, maintaining such complex systems can be challenging.

Cost remains a significant concern for many buyers. While advanced technology improves efficiency, the initial investment can be high. Not all businesses can justify the expense. Additionally, training staff to operate new systems is often overlooked. Balancing innovation with practical limitations is essential for future growth.

Best Centrifugal Pumps in 2026: Market Overview

This chart represents key metrics for centrifugal pumps in 2026, including flow rate, efficiency, head, power, and cost. These values are indicative and reflect market trends projected for optimal performance and value.

Key Features to Consider When Choosing Centrifugal Pumps in 2026

When selecting centrifugal pumps in 2026, key features are paramount. Efficiency stands out. Reports indicate that energy-efficient models can reduce operational costs by 20-30% compared to older designs. This trend is critical as energy prices rise.

Durability is another critical factor. A reliable pump should withstand harsh conditions without frequent breakdowns. Maintenance records show that pumps with higher-quality materials experience fewer failures, translating to lower lifecycle costs. Additionally, size matters. A pump that fits your specific application will perform better. Oversized or undersized units can lead to inefficiencies and higher energy consumption.

Consider control options as well. Modern centrifugal pumps often include smart technology. Sensors and automation improve performance and safety. However, these features can introduce complexity. Not all facilities may possess the required technical skills for advanced management. Balancing features with ease of use is essential.

Top Manufacturers of Centrifugal Pumps: A Comparative Analysis

When analyzing the centrifugal pump market, several manufacturers stand out. According to the latest industry report, the global centrifugal pump market is projected to reach approximately $40 billion by 2026. This growth is fueled by increasing demand in various sectors, including water treatment, oil and gas, and chemical processing. However, not all manufacturers utilize cutting-edge technology.

One major point of concern is efficiency rates. Some manufacturers deliver pumps with only 60% efficiency, while leading competitors achieve as much as 85%. This discrepancy affects total cost of ownership. Users often underestimate maintenance needs. A lower-quality pump may require frequent repairs, undermining its initial cost advantage.

Furthermore, sustainability practices differ widely among top manufacturers. The industry is increasingly pressured to reduce carbon footprints. Yet, some companies lag in adopting eco-friendly technologies. Data shows that nearly 30% of manufacturers still use outdated materials. This presents an opportunity for improvement. Stakeholders should push for better practices and transparency in reporting, ensuring pump performance aligns with environmental goals.

Technological Innovations Shaping Centrifugal Pump Efficiency in 2026

Technological advancements in centrifugal pumps are transforming their efficiency in 2026. A recent industry report highlighted that energy-efficient designs can save up to 20% in operational costs. This is significant for industries reliant on high-performance pumps.

Variable frequency drives (VFDs) are becoming standard. VFDs allow precise control of pump speed, improving energy use. The integration of IoT technology is also on the rise. Sensors collect data in real-time, allowing for predictive maintenance. This can reduce downtime by 30%, as reported in 2022 statistics.

Despite advancements, challenges remain. Many companies struggle to adopt these technologies due to high initial costs. Furthermore, staff training on new systems is often inadequate. For some industries, these obstacles can delay efficiency gains. Investing in training and technology is crucial for sustainable progress.

Industry Applications: Where Centrifugal Pumps Make a Difference in 2026

Centrifugal pumps are vital in various industries. In 2026, their applications span water treatment, agriculture, and oil refining. They create flow by converting rotational energy into fluid motion. This makes them efficient for moving liquids, especially in large volumes.

In the water treatment sector, these pumps help manage systems. They transport water through filtration and chemical processes. Many plants rely heavily on them to maintain operations. However, improper maintenance can lead to efficiency losses. Regular checks are essential for optimal performance.

Agriculture also benefits significantly from centrifugal pumps. Farmers use them for irrigation and crop management. They ensure that water reaches fields effectively. Yet, the energy costs can be high. Exploring energy-efficient models is advisable. Understanding flow rates and pressure requirements is crucial for proper selection.

Tips: Always assess the system’s needs before choosing a pump. Seek professional advice if unsure. Keeping an eye on performance metrics can help prevent issues. This proactive approach can extend the lifespan of your equipment.

Related Posts

-

What is a Centrifugal Pump and How Does It Work

-

How to Choose the Right Centrifugal Pump for Your Industrial Needs

-

How to Select the Right Centrifugal Pump for Your Industrial Applications

-

Understanding the Benefits of Using Above Ground Diesel Storage Tanks in Various Industries

-

How to Choose the Right Gas Transfer Pump for Your Needs

-

Top 10 Gear Pump Types You Should Know About?