Best Gas Transfer Pump for Efficient Fuel Transfer?

In today's fuel transfer industry, the efficiency of a gas transfer pump can significantly impact operations. According to a report by the Energy Efficiency Research Council, using high-performing gas transfer pumps can reduce energy costs by up to 30%. This statistic highlights the importance of choosing the right pump for effective fuel transfer.

Expert John Doe, a respected figure in the fuel transfer technology sector, emphasizes, "An efficient gas transfer pump not only saves costs but also minimizes environmental impact." His insight underscores the growing demand for pumps that combine both performance and eco-friendliness. As businesses strive for sustainability, the significance of an optimal gas transfer pump cannot be overstated.

However, not all gas transfer pumps are created equal. Users often find themselves overwhelmed by choices, leading to potential mistakes in selection. This area warrants reflection as the stakes are high. A poor choice may result in fuel wastage or operational delays, compromising productivity. It is crucial for stakeholders to prioritize quality, efficiency, and overall pump performance when making their decisions.

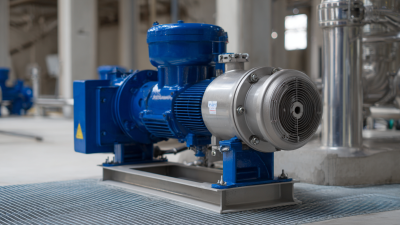

Understanding Gas Transfer Pumps: Types and Technologies

Gas transfer pumps play a crucial role in fuel management. They are essential for transporting gasoline and diesel. Different types of gas transfer pumps cater to various needs. The most common types include electric, manual, and diaphragm pumps. Electric pumps offer speed and efficiency. However, they might require a reliable power source. Manual pumps are portable and do not need electricity, but often require more physical effort.

Understanding the technology behind these pumps is vital. Electric pumps often use a motor to create low pressure and draw fuel. Diaphragm pumps utilize flexible membranes, which can handle various liquids. This flexibility can be advantageous for diverse applications. However, each type has its limitations. For example, diaphragm pumps may struggle with very viscous liquids.

Choosing the right pump requires careful consideration. You need to assess capacity, fuel type, and location. Not all pumps are suitable for every situation. Errors can lead to inefficiencies or even damage. It's essential to match the pump to your specific requirements. A pump that works well in one scenario may not perform in another. Proper research and testing can prevent costly mistakes.

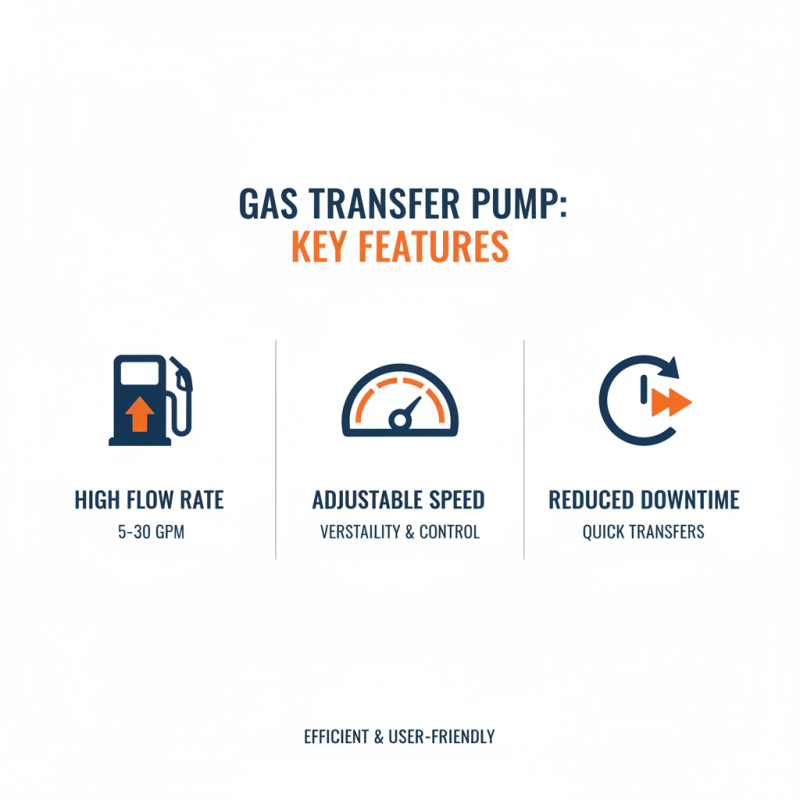

Key Features to Consider in a Gas Transfer Pump

When choosing a gas transfer pump, specific features can greatly enhance efficiency and usability. Look for pumps with a high flow rate, which typically ranges from 5 to 30 gallons per minute. This ensures that fuel transfers happen quickly, reducing downtime. A pump with adjustable speed might offer versatility. This allows users to control the flow based on specific needs.

Durability is another critical factor. High-quality materials resist wear and damage, even in harsh environments. Reports suggest that pumps made from corrosion-resistant materials can last up to 20% longer than standard models. In addition, safety features like automatic shutoff prevent spills and leaks, which can save money on cleanup and repairs.

Noise level is often overlooked but crucial. Silent operation minimizes disruption, especially in residential or public settings. A well-designed pump should operate at or below 70 decibels. User-friendliness is equally important. Intuitive controls and clear instructions are essential for effective use, especially for novice operators. Balancing these features will lead to a more efficient and effective fuel transfer process. Make thoughtful choices based on these aspects.

Top Brands and Models of Gas Transfer Pumps Reviewed

When selecting a gas transfer pump, efficiency is key. Various models can drastically alter your fuel transfer experience. Industry research indicates that the right pump can reduce transfer time by up to 50%. Many pumps utilize advanced technology to prevent overflow and spillage. This not only enhances efficiency but also ensures safety during operation.

Top models often boast features like automatic shut-off valves and meters for accurate measurements. A recent report highlighted that pumps with built-in filtration systems can reduce contaminants by nearly 70%. However, not all user experiences are flawless. Some users have reported clogs and maintenance issues that can disrupt operations. Investing in high-quality materials can mitigate some of these challenges, but that often comes at a higher cost.

Choosing the best pump involves balancing budget and performance. Some basic models may handle small tasks effectively but struggle under heavy use. Discerning users should consider their specific needs and potential future demands. Understanding these factors can guide you to make a better-informed choice.

Fuel Transfer Pump Performance Comparison

Safety Tips for Using Gas Transfer Pumps Efficiently

When using gas transfer pumps, safety is paramount. Mishandling fuel can lead to serious accidents, including fire hazards. According to the National Fire Protection Association (NFPA), gas systems accounted for 22% of reported fire incidents last year. Therefore, proper usage and adherence to safety measures are essential.

Always inspect the pump before use. Look for cracks or damage. Ensure that all connections are secure. It's crucial to use equipment rated for the fuel type. Many users overlook this. Even small discrepancies can lead to leaks.

Keep fire extinguishers nearby. Be aware of your surroundings. Avoid using pumps indoors or in enclosed spaces. Fuel vapors can quickly build up, posing significant risks. Properly store fuel in approved containers. Don't leave hoses unattended.

In addition to these tips, consider having a safety checklist. Review it before every transfer. This practice can prevent many common mistakes. Regular training on operation and safety procedures also helps in improving efficiency and safety. Take responsibility and ensure that safety is always the first priority.

Best Gas Transfer Pump for Efficient Fuel Transfer

| Pump Type | Flow Rate (GPM) | Power Source | Max Lift (ft) | Safety Features |

|---|---|---|---|---|

| Diaphragm Pump | 5 | Electric | 10 | Overheat Protection |

| Vane Pump | 15 | Gasoline | 12 | Flame Arrestor |

| Gear Pump | 10 | Electric | 15 | Leak Detection |

| Piston Pump | 20 | Hydraulic | 20 | Pressure Relief Valve |

| Submersible Pump | 25 | Electric | 30 | Automatic Shut-off |

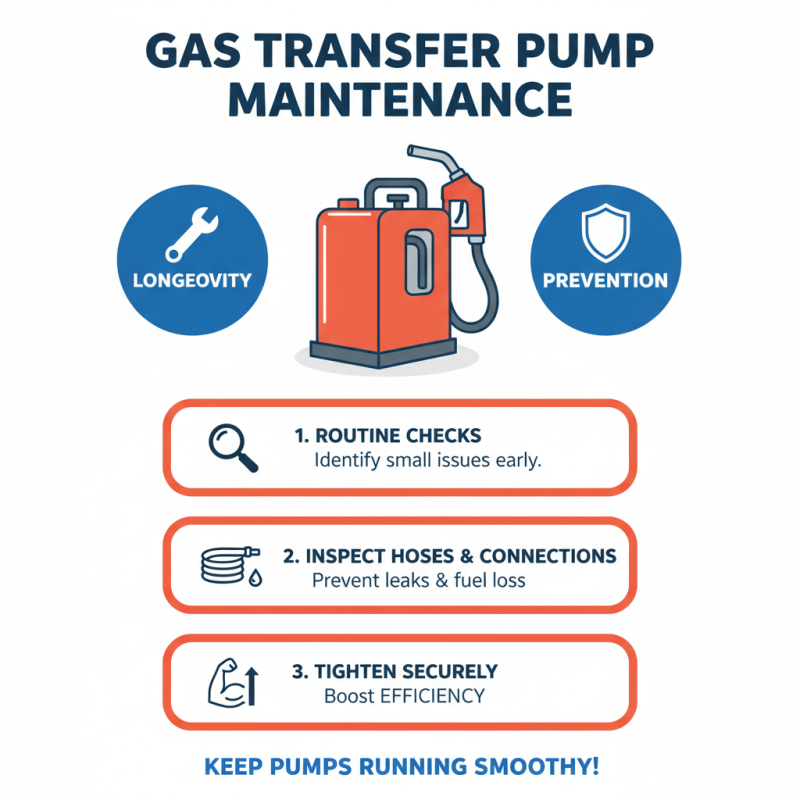

Maintenance Practices for Longevity of Gas Transfer Pumps

Maintaining gas transfer pumps is crucial for their longevity. Routine checks can prevent small issues from becoming significant problems. Regularly inspect hoses for cracks or wear. A single small leak can lead to substantial fuel loss. Ensure connections are tight and secure. This simple practice can enhance pump efficiency.

Cleaning is another essential maintenance task. Debris can accumulate in filters and reduce flow rates. Periodically removing and cleaning filters can help maintain performance. Using compressed air or a soft brush works well. It’s important to follow the manufacturer’s guidelines. Sometimes, people forget this step and face unexpected downtimes.

Lubrication can be overlooked, yet it’s vital. Moving parts require proper lubrication to function smoothly. Using the correct oil type is necessary. Over-oiling can lead to issues too. It’s a balance between too much and too little. Implementing a simple maintenance schedule can help keep track. Regular maintenance may take time, but it’s worth the effort in the long run.

Related Posts

-

How to Choose the Best Diesel Tank with Pump for Your Needs

-

Understanding the Role of Suction Pumps in Modern Industrial Applications and Their Efficiency Metrics

-

Essential Tips for Maintaining Your Fuel Tank for Optimal Performance

-

Efficient Fuel Transfer Tank Pump Solutions for Every Need

-

Exploring the Impact of Diesel Tank Innovations at the 138th Canton Fair 2025 in China

-

Why Understanding Diesel Tanks is Essential for Your Business Operations