Ultimate Diesel Transfer Pump Tips for Efficient Fuel Handling?

In the world of fuel handling, efficiency is critical. The diesel transfer pump plays a vital role in ensuring smooth operations. According to a recent report by the International Fuel Transfer Association, improper handling of diesel can lead to losses of up to 10% due to spillage and evaporation. Expert John Smith emphasizes the importance of precision: "Choosing the right diesel transfer pump is essential for minimizing waste and maximizing output."

Many professionals overlook the nuances of fuel transfer. It’s not just about pumping diesel from point A to point B. The selection of a pump impacts efficiency profoundly. Regular maintenance and proper training can significantly enhance performance. Yet, around 40% of users report issues due to negligence in these areas. Many do not realize that even minor adjustments can lead to major improvements.

Understanding the complexities of a diesel transfer pump can be daunting. Disconnects and leaks are common pitfalls. Reflecting on past experiences is crucial. Mistakes can provide learning opportunities. All stakeholders must prioritize training and knowledge sharing. This assurance not only protects fuel investments but also enhances overall operational efficiency.

Types of Diesel Transfer Pumps and Their Applications

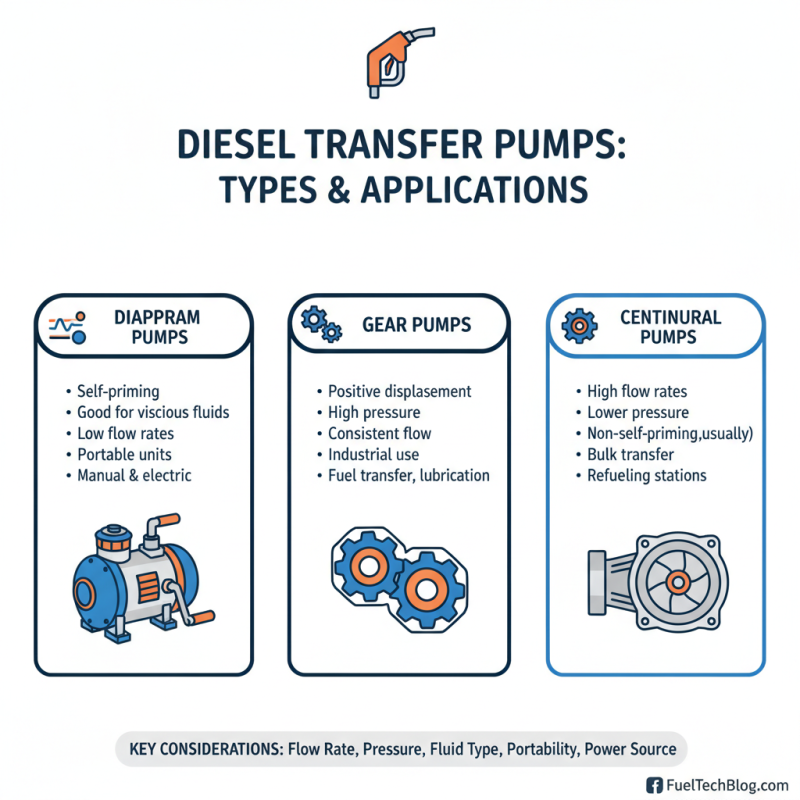

When it comes to diesel transfer pumps, understanding the types and applications is crucial. There are three main types: diaphragm pumps, gear pumps, and centrifugal pumps. Each has unique features that cater to various needs.

Diaphragm pumps are known for their versatility. They handle different fuels and are less prone to contamination. They are great for transferring small quantities. However, they may not perform well under high pressure. Gear pumps, on the other hand, are efficient for high flow rates. They are often used in commercial settings. Yet, maintenance can be a concern, particularly with wear and tear.

Centrifugal pumps are popular for bulk transfers. They offer smooth operation and can move large volumes quickly. However, they require specific installation. If not done properly, it leads to inefficiency. Choosing the right pump depends on the application and environment. It's vital to assess each option critically, considering factors like flow rate and durability.

Key Features to Look for in a Diesel Transfer Pump

When looking for a diesel transfer pump, focus on key features that enhance performance. A robust fuel flow rate is essential. It should deliver fuel quickly without compromising safety. Invest in a pump with a durable construction. Materials should resist wear and corrosion. This ensures longevity, especially in harsh environments.

Consider the pump's portability. Lightweight designs make transportation easy, but they should be sturdy enough to handle tough conditions. Safety features, such as automatic shut-off valves, are crucial too. They prevent spills, reducing environmental risks. Noise levels matter as well. A quieter pump can improve the working conditions significantly.

Reflect on the ease of use. Intuitive controls are a must for smooth operation. Clear instructions simplify setup and maintenance. If a pump is too complicated, it may lead to mistakes. Finally, always check customer reviews. They often highlight real-world experiences, which can guide your decision. Aim for a balance between efficiency and practicality for optimal fuel handling.

Best Practices for Safe and Efficient Fuel Transfer

When dealing with diesel fuel transfer, safety should always come first. According to the National Fire Protection Association (NFPA), improper handling of flammable liquids can lead to serious incidents. Keeping fire extinguishers nearby is essential. Regular training on handling procedures also boosts safety awareness among staff.

Efficient fuel transfer means more than just speed. Temperature affects diesel's viscosity. Warmer diesel flows better, which enhances transfer efficiency. However, overheating can lead to vapor lock issues. The best practice here is to monitor the fuel temperature closely. Using a pump with the right flow rate can minimize fuel wastage and reduce overflow risks.

Many operators overlook equipment maintenance. A worn-out pump can slow down operations, creating unnecessary downtime. According to industry reports, routine maintenance can improve pump lifespan by up to 50%. Therefore, scheduling regular checks should be a priority. Without proper care, costs will escalate, impacting overall efficiency.

Maintenance Tips for Ensuring Optimal Pump Performance

Regular maintenance is crucial for diesel transfer pumps.

First, check the filters often. Clogged filters can reduce pump efficiency. Replace them according to the manufacturer's recommendations or sooner if needed.

Pay attention to any signs of wear and tear. Small issues can escalate quickly if ignored.

Inspect hoses for cracks or leaks. Any damage here can lead to fuel wastage and safety hazards. Tighten connections regularly.

Loose fittings may result in pressure loss and affect performance. It's essential to keep the pump clean and free from debris.

Dirt accumulation can hinder operation.

Monitor performance consistently. If the pump struggles to transfer fuel, it may need servicing.

Take note of any unusual noises. They can signal mechanical problems. Regular checks can prevent costly repairs.

This proactive approach helps keep your pump running efficiently over time.

Troubleshooting Common Issues with Diesel Transfer Pumps

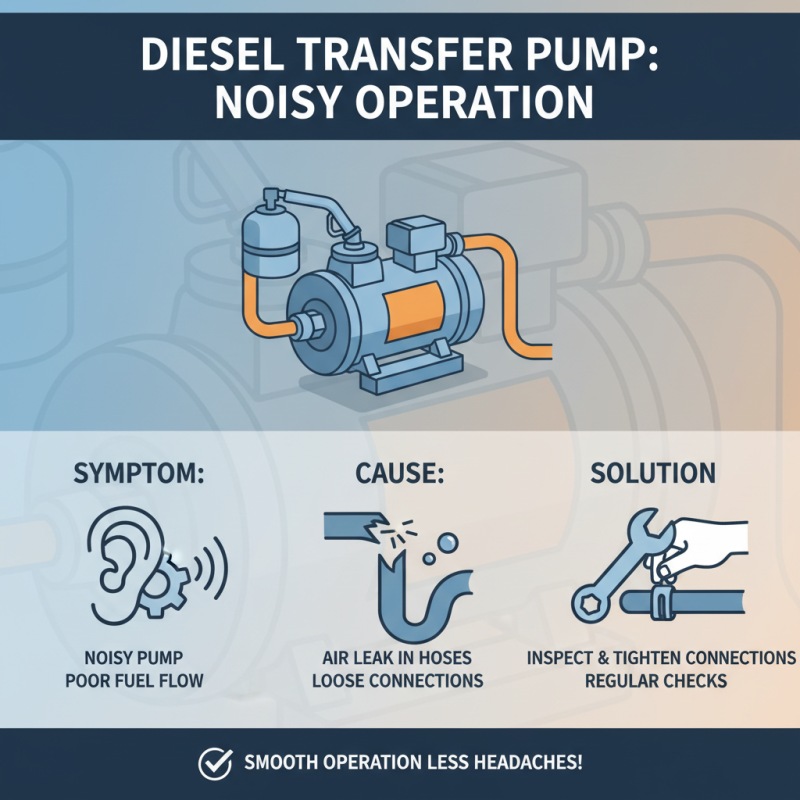

When handling diesel transfer pumps, troubleshooting common issues is essential for smooth operation. A noisy pump can indicate an air leak in the hoses. This can lead to poor fuel flow. Inspecting for loose connections can often fix this problem. A simple check might save a lot of headaches.

Another common issue is reduced fuel pressure. This often stems from blocked filters that need to be cleaned or replaced. Ignoring this can slow down fuel delivery. Check the filter condition regularly, especially in dusty environments. This practice ensures that the pump functions optimally.

Overheating can cause significant damage. Make sure the pump is not running dry. Adding too much fuel can also cause spills. Pay attention to the surrounding area for spills as they pose safety hazards. Regular maintenance checks can help prevent these issues. Small problems can escalate quickly if overlooked. Always keep an eye on the pump's performance.

Related Posts

-

Maximizing Efficiency: The Ultimate Guide to Choosing the Right Diesel Transfer Pump for Your Needs

-

Understanding the Benefits of a Diesel Transfer Tank with Pump for Efficient Fuel Management

-

Maximizing Efficiency and Safety with Diesel Transfer Tanks Featuring Pumps in the Fuel Industry

-

Top 5 Diesel Transfer Tanks with Pump for Efficient Fuel Management

-

Top 10 Tips for Choosing the Right Diesel Tank with Pump for Your Needs

-

7 Reasons to Choose a Diesel Transfer Tank with Pump for Your Business