What is a Dosing Pump and How Does It Work?

Dosing pumps play a vital role in various industries, from agriculture to pharmaceuticals. These devices accurately deliver precise amounts of liquids, crucial for maintaining product quality and efficacy. As John Smith, a leading expert in dosing pump technology, once said, "The accuracy of a dosing pump can make or break a production process."

In simple terms, a dosing pump uses mechanical or electronic means to dispense specific volumes of liquid consistently. Each application can differ widely, yet the fundamental principles remain the same. Many businesses rely on these pumps to ensure the exact dosage for chemical treatments, nutritional supplements, and more. The details matter greatly; even a minor error can lead to significant issues.

However, not all dosing pumps are created equal. Selecting the right one can be challenging. Factors such as compatibility with the liquid, flow rates, and pressure requirements must be considered. It's easy to overlook these details, which can lead to inefficiencies. Understanding how a dosing pump works can guide you in making better choices for your specific needs.

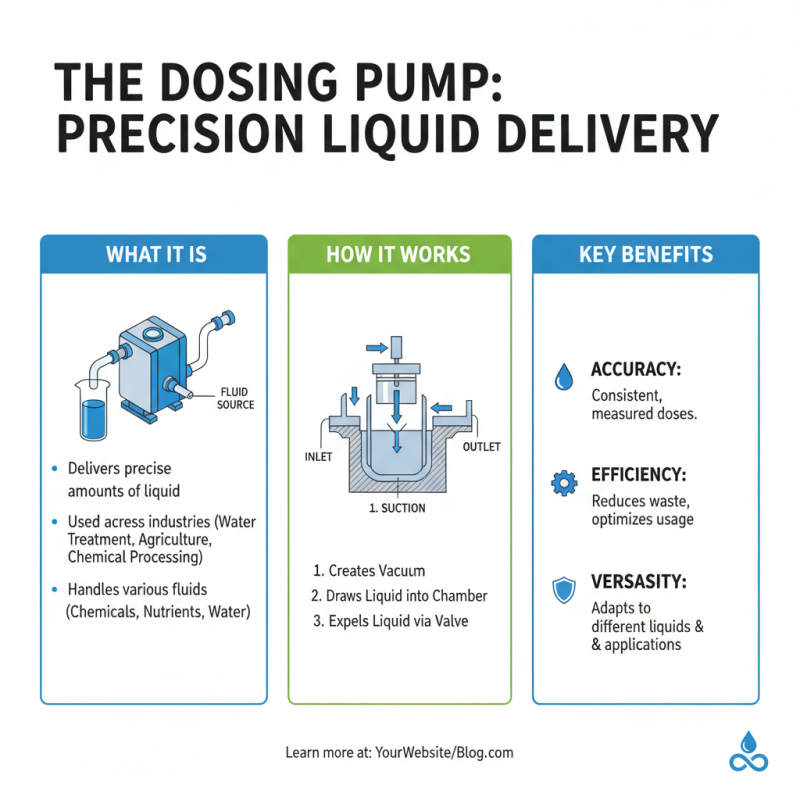

What is a Dosing Pump?

A dosing pump is a device that delivers precise amounts of liquid. It is commonly used in various industries, from water treatment to agriculture. The pump can handle different fluids, including chemicals and nutrients. It works by using a simple mechanism to create a vacuum, drawing liquid into a chamber. When the chamber fills, it expels the liquid through a valve.

Here’s a tip: always check the pump’s calibration. An uncalibrated pump can lead to over- or under-dosing, which might disrupt processes. Regular maintenance is vital to keep the dosing pump functioning correctly.

Dosing pumps also vary in design and capacity. Some models are more suitable for viscous liquids, while others work better with thinner substances. Choosing the right pump can be challenging. It’s essential to consider the application and fluid characteristics carefully.

Tip: not every dosing pump is user-friendly. It may take time to learn the details of your specific model. Understanding the flow rate and pressure settings will help you achieve better results.

The History and Development of Dosing Pumps

Dosing pumps have a fascinating history. Initially, these pumps were simple devices used in agriculture. They ensured a consistent supply of nutrients and chemicals. Over time, industries began to recognize their potential. The demand for precise liquid dosing grew, especially in water treatment and food manufacturing.

As technology advanced, dosing pumps evolved significantly. Early versions relied on mechanical components, which were often imprecise. Modern dosing pumps now employ advanced motorized mechanisms. They offer better accuracy, control, and flexibility. Many now integrate digital systems for real-time monitoring and adjustments.

Tips: When considering a dosing pump, take time to evaluate your specific needs. Not every device is suitable for every application. Testing different types can save time and resources later. Expect some challenges when integrating new systems. Addressing these issues might take patience and creativity.

How Dosing Pumps Function: Mechanics and Components

Dosing pumps are essential devices in various industries. They precisely inject controlled amounts of liquids into a process. The design involves several key components. These include a pump head, motor, and tubing. Each part plays a crucial role in the dosing operation.

The mechanics of a dosing pump are quite fascinating. The motor drives the pump head, creating a suction effect. This action draws liquid into the pump through the tubing. Once filled, the pump forces the liquid out with a specific volume. Adjustable settings allow users to modify the flow rate. This flexibility is important in applications like water treatment or chemical processing.

While dosing pumps offer many advantages, their operation can have challenges. Incorrect calibration may lead to over or under dosing. Regular maintenance is necessary to ensure accuracy. Inadequate inspections can result in failures that disrupt processes. This highlights the need for continuous improvement and monitoring in dosing applications.

What is a Dosing Pump and How Does It Work?

| Component | Function | Typical Applications |

|---|---|---|

| Pump Head | Controls fluid flow and pressure | Water treatment, chemical dosing |

| Drive Mechanism | Converts electrical energy into mechanical motion | Agricultural irrigation, food processing |

| Control System | Regulates flow rate and timing | Pharmaceuticals, waste management |

| Calibration Equipment | Ensures accurate dosing | Chemical manufacturing, laboratory applications |

| Tubing and Fittings | Transfers fluid from the pump to the application | Industrial processes, HVAC systems |

Applications of Dosing Pumps in Various Industries

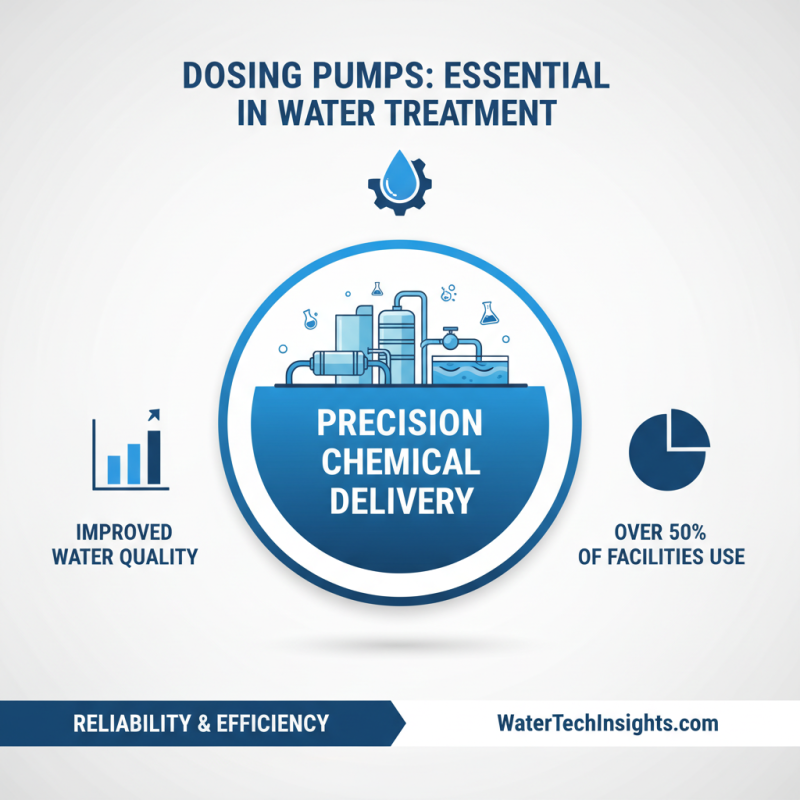

Dosing pumps play a crucial role across various industries, ensuring precise chemical delivery. In water treatment, for example, dosing pumps are vital for adding necessary chemicals. According to a recent industry report, over 50% of water treatment facilities utilize dosing pumps to enhance water quality.

In the food and beverage industry, these pumps ensure consistency in ingredient mixing. They help in adding flavors or preservatives with exact measurements. A study highlighted that industries relying on dosing pumps maintain ingredient accuracy up to 98%. This precision significantly reduces waste and enhances product quality.

Tips: Always maintain dosing pumps for optimal performance. Regular checks can prevent malfunctions. Also, understand the specific needs of your application. This knowledge can guide the correct settings and adjustments. Each application may require different approaches, leading to potential inefficiencies if overlooked. Evaluating pump performance over time is essential; it allows for necessary adjustments and better reliability in processes.

Choosing the Right Dosing Pump for Your Needs

Choosing the right dosing pump for your needs can be a challenge. With various options available, understanding the applications is essential. Recent industry reports indicate that the global dosing pump market is projected to reach a value of $7.25 billion by 2025, driven by increasing demand across sectors like water treatment and pharmaceuticals.

When selecting a dosing pump, consider the fluid characteristics. Viscosity, temperature, and chemical composition can significantly impact performance. For example, a pump designed for low-viscosity fluids might fail with thick substances. Also, take note of the required flow rates. A mismatch can lead to inefficiency and increased operational costs. According to some studies, nearly 30% of users reported underestimating the necessary flow rate, resulting in ongoing issues.

Additionally, do not overlook the maintenance factor. Some pumps require regular servicing, which can be time-consuming. Industry experts suggest that about 15% of pumps are poorly maintained, resulting in operational failures. It's crucial to weigh the cost benefits against reliability. Thoroughly researching specifications and user experiences can save time and money. A well-informed choice leads to smoother operations in the long run.

Related Posts

-

2026 Top Dosing Pump Innovations for Various Industries?

-

Top 5 Dosing Pumps for 2023 Boost Efficiency and Precision in Fluid Management

-

Mastering Dosing Pumps: A Step-by-Step Guide to Optimal Use and Maintenance

-

How to Choose the Right Chemical Dosing Pump for Your Industrial Needs

-

Top 10 Chemical Dosing Pump Questions Answered

-

Top Strategies for Enhancing Efficiency with Metering Pumps