Essential Tips for Choosing a Diesel Transfer Pump?

Choosing the right diesel transfer pump is crucial for efficiency and safety in many industries. According to recent industry reports, the global market for diesel transfer pumps is projected to grow significantly. In fact, it is predicted to reach a valuation of over $500 million by 2025. This growth highlights the increasing reliance on diesel for various applications, from agriculture to construction.

Expert John Smith, a renowned authority in fluid transfer systems, emphasizes the importance of careful selection. He states, "A quality diesel transfer pump can make all the difference in operation efficiency." Selecting a pump requires understanding specific needs. Factors such as flow rate, pump type, and durability must be considered.

Many users overlook these details, leading to costly mistakes. For instance, a pump that is too small can slow down operations. Similarly, durable materials can prevent breakdowns and maintenance issues. Balancing these aspects is essential for a successful investment in a diesel transfer pump. Investing in the right equipment will ensure better performance and reliability in the long run.

Understanding the Basics of Diesel Transfer Pumps

When considering a diesel transfer pump, it’s essential to understand the basics. These pumps are designed to safely transfer diesel fuel from one container to another. They come in various sizes and capacities. Knowing your specific needs is crucial before making a purchase.

One important aspect to consider is the flow rate. This is how quickly the pump can move diesel fuel. Higher flow rates can save time. But, a pump that’s too powerful may not provide the control needed for smaller tasks. It’s all about matching the pump to your requirements.

Safety features are another critical factor. Look for pumps with automatic shut-off mechanisms. These features can prevent spills and reduce environmental risks. A good pump should have proper filtration too. This helps keep the fuel clean during transfer. Remember, investing in quality pays off in the long run.

Key Features to Look for in Diesel Transfer Pumps

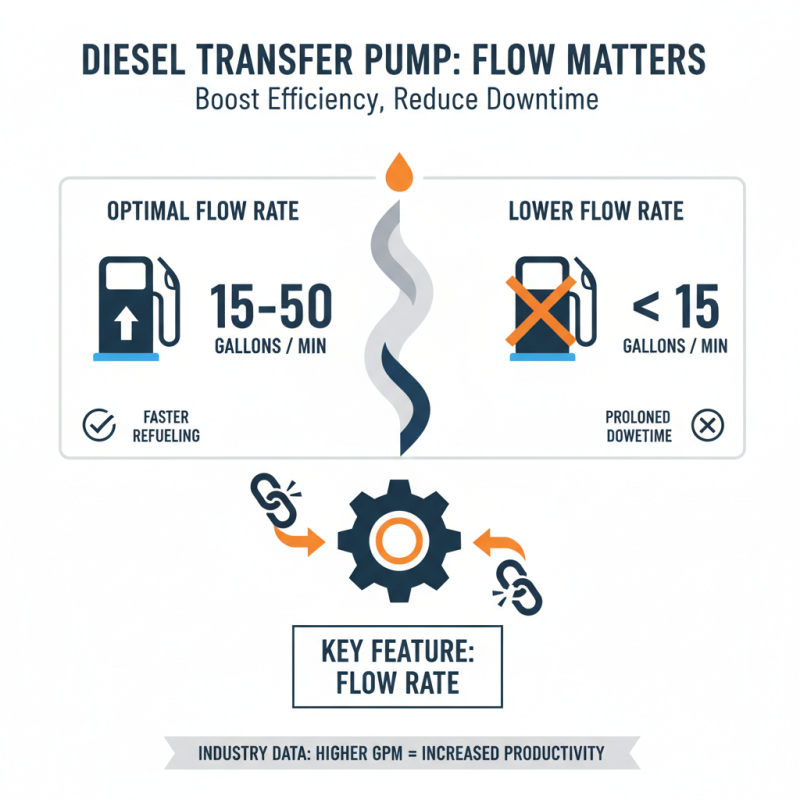

When selecting a diesel transfer pump, the features matter significantly. The pump's flow rate is a crucial aspect. A higher flow rate, typically between 15 to 50 gallons per minute, is optimal for efficiency. According to industry data, pumps with lower flow rates may lead to prolonged downtime, impacting productivity.

Portability is also essential. Many pumps weigh over 50 pounds. A lightweight, compact design enhances mobility. Look for a sturdy handle for easy transport. Moreover, the power source is vital. Choose between electric and fuel-powered options. Each has pros and cons. Electric pumps offer quieter operation but require access to a power source. In contrast, fuel-powered pumps may provide more flexibility on job sites.

Durability cannot be overlooked. Pumps constructed from high-quality materials tend to last longer. Corrosion-resistant designs are essential to withstand harsh conditions. Additionally, consider the safety features. A built-in automatic shut-off function can prevent spills and accidents. Neglecting these specifications could lead to malfunction and higher replacement costs over time. Make sure to weigh each feature carefully before settling on a pump.

Assessing the Pump's Flow Rate and Capacity

When selecting a diesel transfer pump, assessing the flow rate and capacity is crucial. Flow rate refers to how quickly the pump can move diesel. It's typically measured in gallons per minute (GPM). A higher flow rate means faster refueling, which is beneficial for operations with heavy machinery. However, you should not select the highest flow rate without considering your needs.

Consider the capacity you actually require. For example, a better fit might be a medium-sized pump that balances speed and efficiency. Too powerful pumps may lead to overflow risks or inefficient fueling practices. Make sure to match the pump with your storage tank size as well. Keeping your backlog needs in mind can avoid purchasing a pump that’s either too small or excessively large.

Many users overlook the specifications listed. While some pumps boast impressive figures, real-world performance can differ. Reading reviews and seeking user experiences can help refine your choices. Reflect on previous experiences with pumps as well. Did you face delays or issues with flow consistency? Taking these aspects into account is vital for making an informed decision.

Essential Tips for Choosing a Diesel Transfer Pump

This bar chart illustrates the flow rates and capacities of various diesel transfer pumps. Understanding these metrics can help in selecting the right pump based on your needs.

Evaluating Pump Durability and Maintenance Requirements

When selecting a diesel transfer pump, evaluating durability and maintenance is crucial. Reports from the American Petroleum Institute show that pumps can fail prematurely due to poor maintenance practices. Depending on the model and usage, the cost of repairs can easily escalate. A well-maintained pump not only lasts longer but also operates more efficiently, saving money on fuel and energy.

Durability factors include materials, design, and environmental conditions. Many pumps are made from aluminum or stainless steel, which offer varying levels of corrosion resistance. A study indicated that pumps exposed to extreme temperatures may degrade faster. Maintenance requirements vary widely, with some pumps needing regular filter changes and others requiring a full inspection every few months. Ignoring these needs can lead to performance drops.

Users often overlook the importance of documentation in maintenance routines. Keeping track of service records can help identify issues before they become critical. A survey revealed that 70% of pump operators do not maintain logs, potentially jeopardizing performance. Regular checks can increase reliability and efficiency. A small effort in maintenance today can prevent significant repairs tomorrow.

Choosing the Right Power Source for Your Diesel Pump

When selecting a diesel transfer pump, the power source is crucial. Many users overlook this aspect. It's essential to match the pump's power requirements with the available energy options. According to a recent industry report, over 70% of diesel pump users prefer electric sources due to their efficiency and reliability. However, some settings require portable solutions. Battery-operated pumps may suit specific applications, especially where mobility is key.

Consider the power output and voltage specifications. A mismatch can lead to inefficiencies or damage. Research shows that choosing the right power source can enhance pump longevity by up to 30%. Diesel-powered pumps are robust and ideal for heavy-duty tasks. Yet, they often come with higher operational costs. User feedback indicates that running costs can be a concern, especially in continuous use scenarios.

Some operators face installation challenges. Not all sites provide compatible power sources. This situation can complicate pump usage. It's essential to evaluate the environment before purchasing. Engaging a professional for evaluations can minimize costly mistakes. It’s worth noting that electricity supply fluctuations can disrupt operations unexpectedly. A solid power source is non-negotiable for seamless performance.

Related Posts

-

Ultimate Diesel Transfer Pump Tips for Efficient Fuel Handling?

-

Exploring the Benefits of Air Operated Diaphragm Pumps: A Comprehensive Guide for Industrial Applications

-

2026 Best Progressive Cavity Pump Options for Your Needs?

-

7 Reasons to Choose a Diesel Transfer Tank with Pump for Your Business

-

What is an Air Operated Diaphragm Pump and How Does It Work?

-

How to Choose the Right Gas Transfer Pump for Your Needs