Top 10 Gear Pump Types You Should Know About?

In the world of fluid dynamics, gear pumps are indispensable. Known for their efficiency, they play a crucial role in various industries. John Smith, a renowned expert in the gear pump field, once stated, "Choosing the right type of gear pump can make a huge difference in performance."

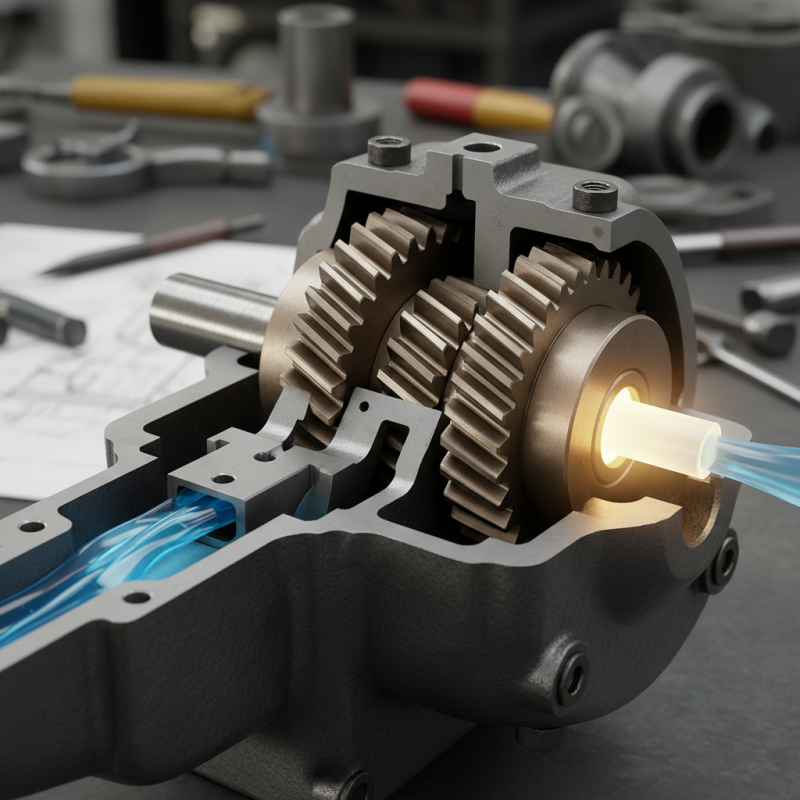

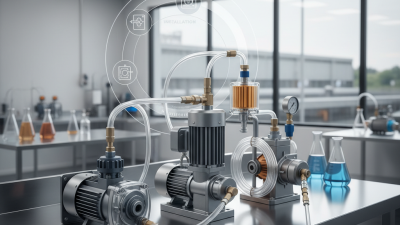

Gear pumps operate by utilizing two interlocking gears. These gears draw fluid into the pump and then push it out. Different types of gear pumps cater to various applications. For example, some pumps excel in handling viscous fluids while others are perfect for low-viscosity liquids. This diversity highlights the importance of knowing the right type for your specific needs.

However, not all gear pumps are created equal. Factors such as material selection, size, and design can influence performance. It’s critical to reflect on these aspects during selection. Additionally, using the wrong type can lead to inefficiencies. Understanding the nuances of gear pump types can significantly impact operational success.

Overview of Gear Pump Basics and Functionality

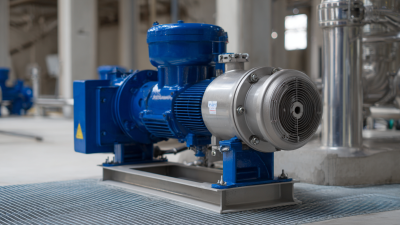

Gear pumps play a vital role in various industrial applications. Understanding their basics is essential. A gear pump operates by using the meshing of gears to pump fluid. This simple yet effective mechanism is widely used in hydraulic systems. The efficiency of gear pumps can reach up to 90%. However, proper maintenance is crucial to sustain this efficiency.

One key aspect to consider is the type of fluid being pumped. Viscosity affects how the pump performs. Sticky or viscous fluids can lead to increased wear. This, in turn, might cause system failures. Regular inspection can help mitigate these issues.

Tips: Always check fluid compatibility. Using the wrong fluid can damage the pump. Furthermore, consider the pump speed. Higher speeds can lead to overheating. Ensure you're within the recommended operating range. Overheating can shorten the pump's lifespan significantly. Remember, a little care goes a long way in enhancing performance.

Top 10 Gear Pump Types You Should Know About

Common Applications of Gear Pumps in Various Industries

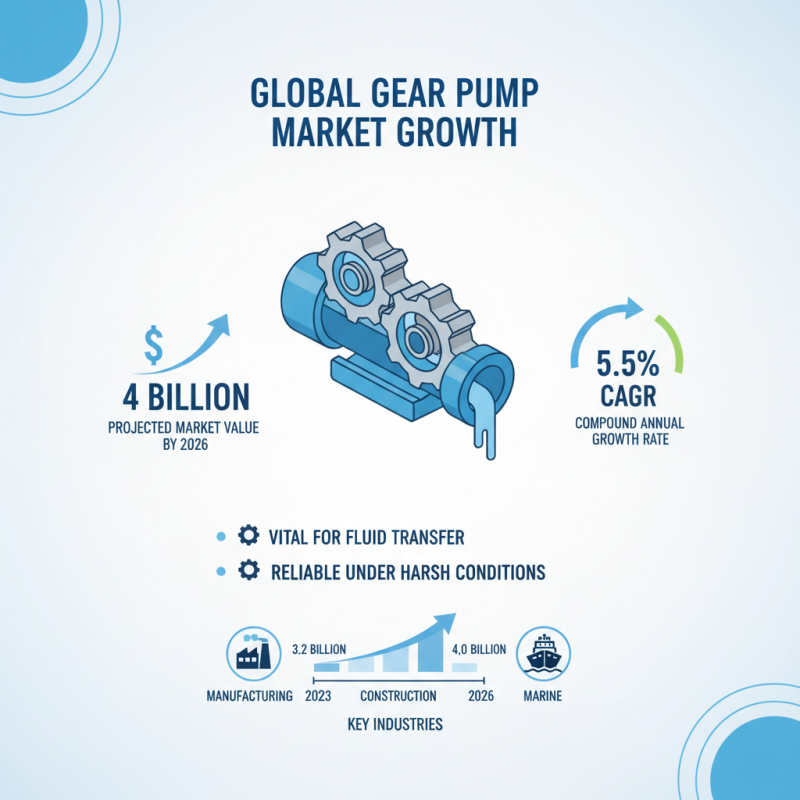

Gear pumps are vital components in various industries. They provide reliable fluid transfer in challenging conditions. According to a recent market research report, the global gear pump market is projected to reach $4 billion by 2026, growing at a CAGR of 5.5%.

In the oil and gas sector, gear pumps are crucial for liquid transfer in drilling applications. They handle high viscosities and pressures effectively. A survey indicated that around 30% of oil extraction operations utilize gear pumps for efficient fluid management.

In the food and beverage industry, these pumps ensure quality and safety. They move liquids without damaging sensitive ingredients. However, challenges exist in maintaining hygiene and preventing contamination. A study found that nearly 25% of food processing facilities reported issues with pump sanitation, highlighting the need for regular maintenance and monitoring.

Different Types of Gear Pumps and Their Unique Features

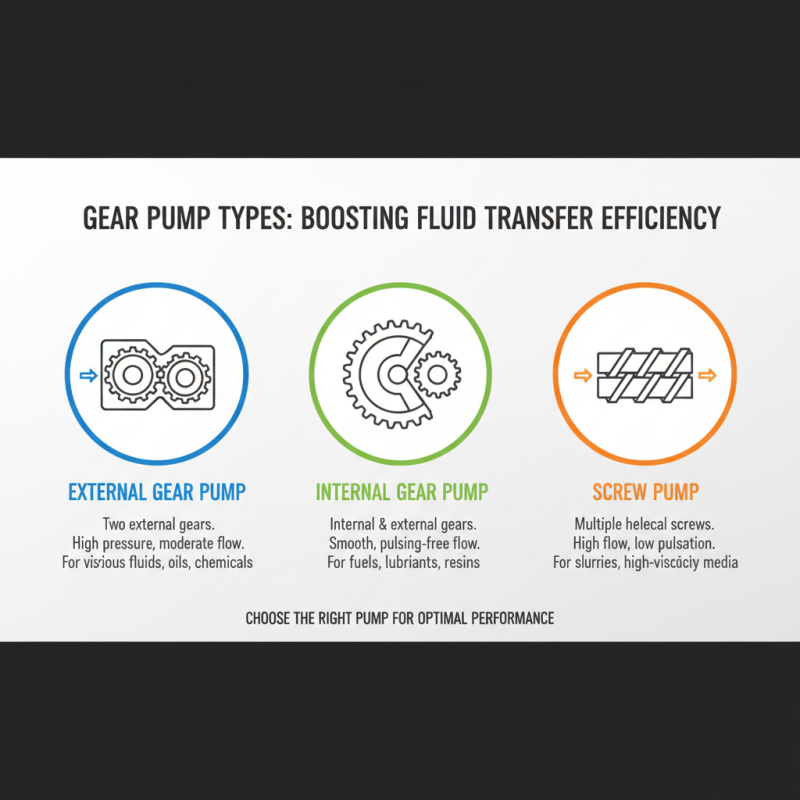

Gear pumps are vital in numerous industries, boasting various types that cater to specific needs. Understanding these types can enhance efficiency and performance in fluid transfer applications. The most common types include external gear pumps, internal gear pumps, and screw pumps, each with unique features.

External gear pumps are popular for their simplicity and reliability. They consist of two interlocking gears that move fluid effectively. Their ease of maintenance makes them favored in many sectors, from automotive to hydraulic systems. In contrast, internal gear pumps excel in handling more viscous fluids. Their design allows for quieter operation, which is crucial in sensitive environments.

**Tip:** Always consider fluid characteristics when selecting a pump. For example, a higher viscosity fluid may require an internal gear pump to maintain efficiency.

Screw pumps are noteworthy due to their ability to handle various fluid types, including those with entrained solids. They offer a gentle pumping action, ideal for delicate applications. However, they may not be as widely recognized, which could lead to missed opportunities in certain projects.

**Tip:** Evaluate the installation environment. Factors such as temperature and pressure can drastically affect performance.

It's essential to choose the pump type carefully, as each has its advantages and limitations. Research indicates that selecting the wrong pump can lead to inefficiencies, increasing maintenance costs and downtime. Understanding these differences will empower informed decision-making in pump selection.

Factors to Consider When Choosing a Gear Pump

When selecting a gear pump, several critical factors must be considered. The type of fluid being pumped is paramount. Fluids with high viscosity, for instance, require pumps specially designed for that purpose. According to a 2022 industry report, over 40% of gear pump failures stem from improper fluid selection. These failures can lead to costly downtime.

Another factor is the required flow rate. Each application has specific demands. A pump that cannot meet these demands may lead to inefficiencies. In fact, research indicates that 30% of equipment inefficiencies are linked to mismatched flow rates. Additionally, material compatibility is essential to avoid corrosion or degradation. The wrong materials can severely limit pump life and performance.

Operating conditions must also be assessed. Consider temperature, pressure, and environmental impact. Extreme conditions can stress pumps beyond tolerable limits. A study in 2023 revealed that nearly 25% of pumps fail due to operational oversights. Proper attention to installation and maintenance practices is equally crucial. Neglecting these details can produce detrimental outcomes, causing unplanned maintenance and higher operational costs.

Maintenance Tips for Longevity of Gear Pumps

Gear pumps are essential in various industries, known for their ability to move fluids efficiently. To ensure their longevity, regular maintenance is crucial. Start by checking the oil levels. Insufficient lubrication can lead to premature wear. Clean the pump housing to avoid debris buildup. Dirt can cause blockages, straining the pump unnecessarily.

Listen for unusual noises during operation. A grinding or whining sound can indicate issues. Addressing these sounds early can save time and money. Regularly inspect seals and gaskets as well. Worn components can lead to leaks. Check connections and fittings for tightness. Loose parts may result in inefficiency and potential damage.

Consider also the pump's operating conditions. High temperatures can degrade materials over time. Ensure that the pump operates within recommended parameters. Monitor fluid types as well. Using unsuitable fluids can accelerate wear and tear. Inconsistencies in routine checks can lead to unexpected failures. Even small oversights can have significant impacts on performance.

Related Posts

-

10 Essential Tips for Choosing the Right Gear Pump for Your Applications

-

How to Choose the Right Gear Pump for Your Application Needs

-

Top Gear Pump Types Explained for Efficient Fluid Transfer?

-

Top 10 Chemical Dosing Pump Questions Answered

-

Understanding the Role of Suction Pumps in Modern Industrial Applications and Their Efficiency Metrics

-

Ultimate Diesel Transfer Pump Tips for Efficient Fuel Handling?